Legal Metrology

DEFINITION:

Legal Metrology is that part of metrology that is subject to legal/regulatory control. It is defined in the International Vocabulary of Legal Metrology as that part of metrology relating to activities which result from statutory requirements and concern measurement, units of measurement, measuring instruments and methods of measurement which are performed by competent bodies.

COVERAGE:

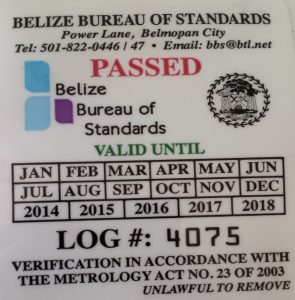

Considering the growth of the Belizean markets, the coverage/scope of legal metrology would naturally be extended to address, resources permitting, weighing and measures devices/instruments beyond those at your local convenient store. Today, the Belize Bureau of Standards verifies devices and instruments used in production as well as those used in the service industry. Routine verification exercises are carried out at the Sugar, Citrus, Flour, Rice facilities/plants and Feed Mills. In the service industry, exercises are carried out at local and international airlines, private medical facilities, post offices etc., fuel stations, LPG depots.Instruments/Devices that pass the verification exercise are affixed with a sticker of accuracy. This is a tamper-proof BBS sticker that carries a unique serial number and the period for which the sticker is valid.

Metrology Verification Sticker

Those that are not, are treated accordingly as the law provides for e.g. A fuel dispenser or pump at a service station will be secured with a wire seal to prevent any further dispensing of fuel, until the necessary maintenance can be undertaken.

SOME OF THE VERIFICATION CONDUCTED ARE AS FOLLOWS:

- Verification of Commercial Scales – Verification activities are carried out at retail establishments on equipment used to sell products by mass. Verification are carried out twice per year.

Verification of commercial scales are conducted on a regional basis as follows:

REGION 1 – Northern Districts (Orange Walk and Corozal): March-April and September-October

REGION 2 – Central Districts (Belize and Cayo): January-February and July-August

REGION 3 – Southern Districts (Stann Creek and Toledo): May-June and November-December

*The rotation is relevant to scheduled verification activities. The BBS may exercise it prerogative to conduct a verification exercise in any establishment in any jurisdiction at any time if it is deemed necessary.

- Verification of Fuel Pumps – Verification activities are carried out at service stations countrywide. Verification are carried out twice per year. A tamper proof BBS sticker is placed on all equipment which pass verification.This mark carries a unique serial number and the period for which the sticker is valid.

Affixing of BBS Verification Sticker “Approved for Accuracy”

All pumps that pass verification are also sealed with a BBS wire seal with a serial number to ensure that the pumps are not tampered with in between verification.

BBS Wire Seal

- Verification of LPG Equipment – At present, there are two types of equipment used in the sale and distribution of LPG which the BBS verify. Scales used to sell products as per by-laws are subject to initial and subsequent verification. These equipment are verified twice per year and the equipment owner is charged a small fee for this service. In addition to scales, BBS personnel also conduct verification services on flow meters installed in LPG plants and depots as well as those installed on mobile distribution units. The verification of meters are not subject to regulations at this time.

- Verification of Pre-packaged Goods – Verification of pre-packaged goods is meant to ensure that items packaged at the point of retail sale are accurately marked. This exercise is conducted simultaneously with the verification of commercial scales. Therefore, the frequency of scheduled coverage indicated above applies.

- Other Verification Services – BBS compliance personnel also conduct verification services for establishments when requested. Most of these verifications are conducted on industrial scales and high capacity scales (weigh Bridges) used by major industries.

Compulsory Standards

- Inspections/Field – Inspections are conducted in the retail market, ports of entry and production/packaging facilities to verify compliance with relevant compulsory standards. Primary standards against which inspections are conducted include; Belize National Specification Part 2 Labelling of Pre-Packaged Goods, Belize National Specification Part 3 Labelling of Pre-packaged Food, Belize National Specification Part 4 Labelling of Retail Packages of Cigarettes, Belize National Specification Part 5 Labelling of Brewery Products, Belize National Specification for Carbonated Beverages Belize National Specification for Bottled/Packaged Water, Belize Standard for Rice specification.

-

- Label Evaluation – Producers, importers, wholesalers and distributors operating in Belize submit product labels to the BBS for evaluation. Labels are assessed against relevant labelling standards as follows; Belize National Specification Part 2 Labelling of Pre-Packaged Goods, Belize National Specification Part 3 Labelling of Pre-packaged Food, Belize National Specification Part 4 Labelling of Retail Packages of Cigarettes, Belize National Specification Part 5 Labelling of Brewery Products, Belize National Specification for Carbonated Beverages Belize National Specification for Bottled/Packaged Water, Belize Standard for Rice specification. A compliance report is generated and provided to the entity submitting the label for evaluation. It is the responsibility of that entity to ensure that all products produced, sold or distributed in Belize meet the requirements of the standards.

- Testing – At present, the BBS is in the process of developing testing capabilities for products which are subject to compulsory standards. Current emphasis is on the testing of LPG (density). This is used to assess compliance of this product with the Belize National

Legal Metrology

Legal Metrology Compulsory Standards

Compulsory Standards